Correlation with printing and converting failures due to impulses, impacts and shocks is usually excellent. While static/dead-weight tests, such as tensile and Z-direction tensile., focus on the ultimate yield value of a sample, the Internal Bond test responds to the semi-elastic nature and behavior of paper and board. Materials that are somewhat elastic provide during rupture absorb more energy and exhibit stronger behavior in real-world situations. A key element of this dynamic test is speed: at the beginning of the specimen rupture, the falling pendulum is moving at a speed more than 6500 times as fast as the relative jaw movement of a tensile tester. This produces correlation with many printing and converting failures that typically occur in fractions of a second.

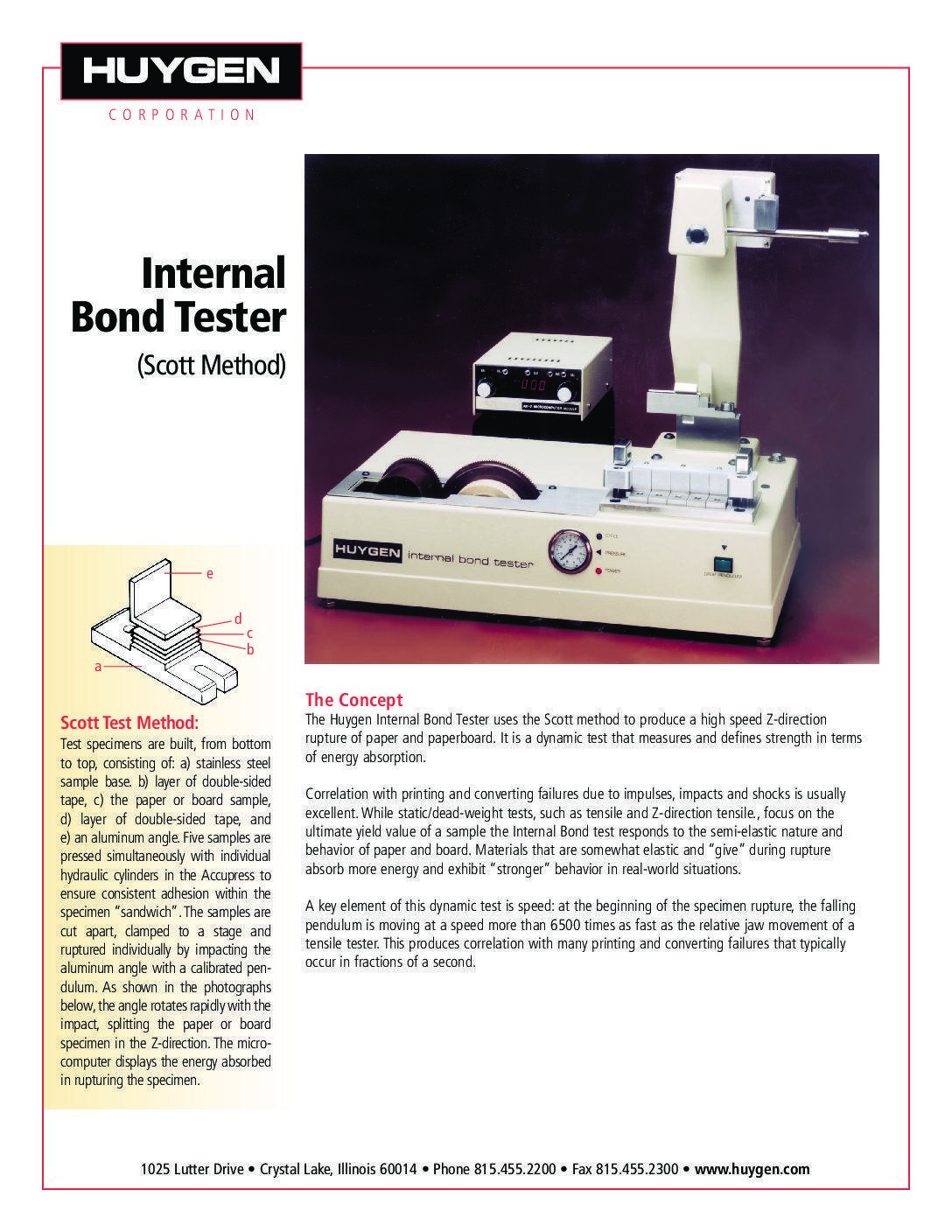

Huygen Internal Bond Test:

Model 1314 Internal Bond Tester utilizes the Scott method to produce a high-speed Z- direction rupture of paper and paperboard. It is a dynamic test that measures and defines strength in terms of energy absorption.

Internal Bond Tester Applications:

From its inception, the Scott Internal Bond Tester has been used to monitor the effects of dry strength additives and to evaluate stock preparation and refining. In recent years, applications have expanded to include prediction of blistering for coated web offset grades, picking, manufacturer’s flap failures, delaminations, ply separations and “shock induced” failures encountered in paper and board converting operations.

The common denominator is that these are high speed phenomena/failures that occur in milliseconds. In addition to correlations with customer complaints, in-mill processing trouble-spots are of growing interest.

Examples of dry-end analysis are monitoring Z-direction strength deterioration due to calendering or the application of relatively brittle coatings. The increasing use of recycled fiber and dry strength additives in both paper and board open even more applications and create economic value for the test today. At the product research and development level, sequential photographs of the ruptures can further enhance analysis and understanding.

Interested in knowing more about Huygen Solutions? We will help you to make good choices that meet your production needs.

Contact Haarla Experts:

Contact us about solution

Whatever the industry, we know what’s cooking.

Text for placeholder, complimenting the brand impression on the home page and inviting to contact.

- Food

- Water & Air

- Machinery & Equipment

- Industrial

- Health & Wellbeing