VisioPointer® is a high-end, state-of-the-art quality control system designed for thorough quality control of food packaging. The system is based on TriVision’s advanced machine vision technology, making it a highly reliable, accurate and efficient quality control system. With light and camera setups both above and below the unit’s built-in conveyor belt, VisioPointer® can inspect labels and artwork, barcodes and printed date markings both on the top and the bottom of different types of food packaging. VisioPointer® also inspects the package seals of for example thermoformed packaging, tray sealed packaging and vacuum skin packaging.

Haarla is the official distributor of Trivision machinery in Finland. For fish, cheese, ready-to-eat meals and meat sectors we supply following machine vision inspection of food packaging:

VisioPointer

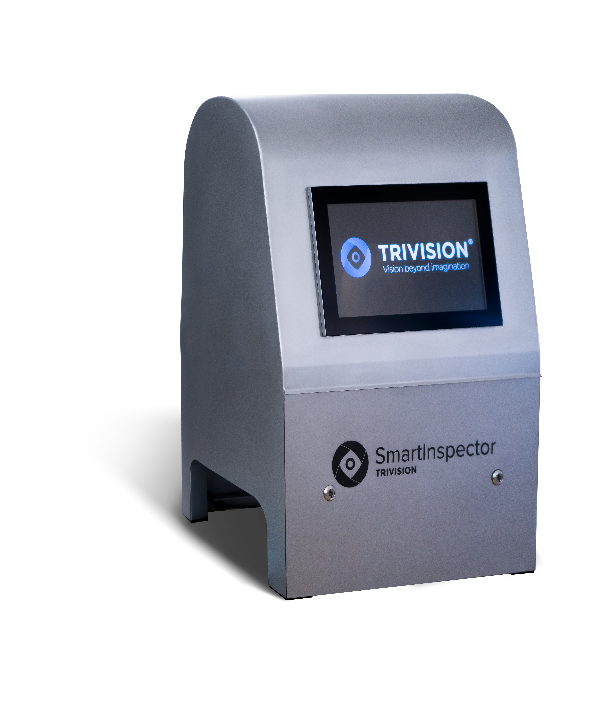

SmartInspector®

SmartInspector® is a high-end quality control system used for label and artwork inspection, barcode inspection and print inspection of different types of packaging. With a compact, minimalistic design, the SmartInspector® is a plug & play solution that is easy to implement onto any existing production line because of a small footprint. The system comes in different widths and is mounted with brackets onto an existing conveyor belt.

Interested in knowing more about Trivision Solutions? We will help you to make good choices that meet your production needs.

Contact Haarla Experts:

- Food

- Water & Air

- Machinery & Equipment

- Industrial

- Health & Wellbeing