Paprima enjoys repeat orders from the most prominent paper and board manufacturing companies and from major paper machine builders, for the largest, fastest, and most productive machines on any paper grade. All products are entirely built-in corrosion proof stainless steel, even when installed on the dry-end of the paper machine.

Pulp and Paper Solutions

The Reel-Jet™

High-pressure water-jet turn-up system

The Reel-Jet™ system provides the highest turn up efficiency in the market and significantly reduces spool loss. The Reel-Jet™ water jet turn up system can operate jointly with conventional air goosenecks, tape turn ups, and air assisted on level rail turn up systems, making the Reel-Jet™ the most flexible water jet multi mode turn ups. There are various possible turn up methods with the Reel-Jet™ system.

Common methods

- Cross cutting, chevron tip creation (cutting nozzles cross one another)

- On level rail turn-up

- Pulper turn-up (following a sheet break)

- Parallel cutting for light hygiene grades (no cross of cutting nozzles)

- Parallel cutting for heavier publication/board grades (no cross of cutting nozzles), with possible auxiliary water-jet slasher

- Patented X-Cut profile to eliminate flying paper on parent roll

Advantages:

- Reliable process performance

- Process not affected by paper machine speed or basis weight

- Symmetrical turn-up reduces spool loss

- Minimized parent roll loose / flying paper

The Power Jet™ Cleaner

Engineered fabric cleaning solutions

The Power Jet™ Cleaner is an advanced design which cleans the dryer fabric continuously. Its purpose is to remove contaminants which reduce fabric permeability as well as to remove “stickies” at the highest level possible. These “stickies” are becoming more and more problematic as the recycled content in the pulp furnish increases. Substantial savings and a more uniform end-product are the result of the Power-Jet™ Cleaner usage. The paper machine dryer section is a major consumer of steam and maintaining the highest possible dryer fabric permeability is one way to maximize heat transfer to the sheet of paper and saves energy. In the forming section the version of our continuous cleaner drastically reduces the amount of water used with common cleaners while keeping the fabric optimally cleaned. The Power-Jet™ Cleaner helps in achieving these objectives.

The complete package offered by Paprima is taking all of the following design criteria into consideration:

- Dislodging contaminants from the fabric

- Removing those contaminants from the process, away from the machine

- Drying the fabric and removing excess water

The final product addresses and solves problems experienced by papermakers with available systems on the market today. In short, these advantages are:

- Higher dryer fabric permeability

- Continuous cleaning operation

- Better end-product quality

- Energy savings

- Maintenance cost savings

- “Stickies” removal

The Trim-Jet™ H

Automated or manually adjusted water-jet sheet slitter and edge-trimmer

The Trim-Jet™ H is an automated or manually adjusted water-jet sheet slitter and automated edge-trimmer, which cuts the web without reducing sheet bulk. Paprima is the only company offering edge trimming at high machine speed.

Advantages:

- Increases machine production by 5% at the same bulk

- Increases machine production if the winder speed is limited

- Provides dust-free slitting

- Slits/trims an oscillating sheet

- Cuts rolls down to a small as 200mm (8” wide), and narrower if needed

- Cuts narrower trim – down to 20mm

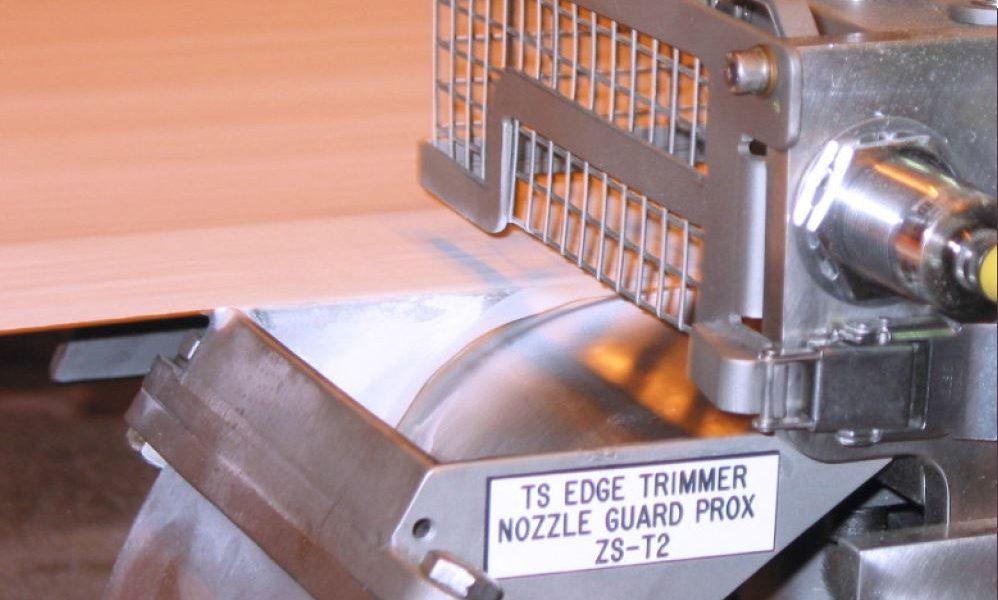

Trim-Jet™ P

Automated water-jet edge-trimmer

Automated water-jet edge-trimmer – Trim-Jet™ P, is specifically designed for publication grades (printing & writing, paperboard, pulp, etc.). The Trim-Jet™ P is an automatically adjusted water-jet edge-trimmer, usually equipped with a servo-motor for accuracy and repeatability.

Advantages:

- Removes edge defects that can cause sheet breaks at the size press or the winder

- Enters the sheet when starting to trim without causing sheet breaks

- Not affected by sheet oscillation – critical on high-speed machines

- Not affected by sheet speed, moisture, caliper or tension

- Trims an oscillating sheet

- Cuts narrower trim – down to 15 mm

Jet-X™ 2000

Engineered water-jet tail cutting solutions for all paper grades

The Jet-X™ 2000 is an automated, single cut water-jet tail cutter with precise tail positioning capability. Jet-X™ tail cutters are operating worldwide on paper grades including:

- Directory paper

- Newsprint

- SC

- LWC base

- LWC coated

- Coated fine paper

- Linerboard

- Paperboard

- Corrugating medium

- Pulp

There is no mechanical stressing off the sheet during the cutting process. A high-pressure water-jet cuts the paper at high pressure through a small diameter diamond nozzle. The Jet-X™ has the following advantages over mechanical tail cutters:

- Not affected by sheet oscillation – critical on high-speed machines

- Not affected by sheet speed

- Not affected by sheet moisture

- Not affected by sheet caliper

- Not affected by sheet tension

- Can cut on the dryer cylinder as well as in the “open draw”

- Prevents sheet breaks from clean water-jet cut

- Dust free cutting

- No blade sharpening

Jet-X™ 4000

An automated, dual cut water-jet dry-end tail cutter.

The Jet-X™ 4000 is an automated, dual cut water-jet tail cutter with precise tail positioning capability and ability to move the tail away from the tending side edge before widening out. Jet-X™ tail cutters are operating worldwide on paper grades including :

- Directory paper

- Newsprint

- SC

- LWC base

- LWC coated

- Coated fine paper

- Linerboard

- Paperboard

- Corrugating medium

- Pulp

There is no mechanical stressing off the sheet during the cutting process. A high-pressure water-jet cuts the paper at high pressure through a small diameter diamond nozzle. The Jet-X™ has the following advantages over mechanical tail cutters:

- Not affected by sheet oscillation – critical on high-speed machines

- Not affected by sheet speed

- Not affected by sheet moisture

- Not affected by sheet caliper

- Not affected by sheet tension

- Can cut on the dryer cylinder as well as in the ‘open draw’

- Prevents sheet breaks from clean water-jet cut

- Dust free cutting

- No blade sharpening

Jet-X™ PZR

An automated, single cut low pressure water-jet wet-end tail cutter

The Jet-X™ PZR is an automated, single cut low pressure water-jet wet-end tail cutter with precise tail positioning capability.

Installed and cutting over forming fabric ahead of the couch roll or installed and cutting under the press fabric.

The Jet-X™ PZR wet-end tail cutters are operating worldwide on paper grades including:

- Directory paper

- Newsprint

- SC

- LWC base

- LWC coated

- Coated fine paper

- Linerboard

- Paperboard

- Corrugating medium

- Pulp

Advantages:

-

- Heavy duty construction

- Compact design

- Easy slide-out feature allows “in situ” servicing

Jet-X™ 1000 K/R

Automated, single cut dry-end tail cutter with precise tail positioning capability

The Jet-X™ 1000 K/R is an automated, single cut blade dry-end tail cutter with precise tail positioning capability.

- Fits most dryer pockets

- Patented cutting head with air injector ensures positive sheet support

- Motor can be installed on drive or tending side of machine

- All critical components are cooled ensuring reliable service life

Jet-X™ tail cutters are operating worldwide on paper grades including:

- Directory paper

- Newsprint

- SC

- LWC base

- LWC coated

- Coated fine paper

- Linerboard

- Paperboard

- Corrugating medium

- Pulp

Advantages:

- Automatic tail positioning to programmed widths

- Variable speed drive system includes an optical encoder for precise position control

- Equipped with blade ‘quick change’ features

- Removable hand-crank installed on either drive side or tending side

- Single inner beam slide-out assembly for maintenance

Interested in knowing more about Paprima Solutions? We will help you to make good choices that meet your production needs.

Contact Haarla Experts:

- Food

- Water & Air

- Machinery & Equipment

- Industrial

- Health & Wellbeing