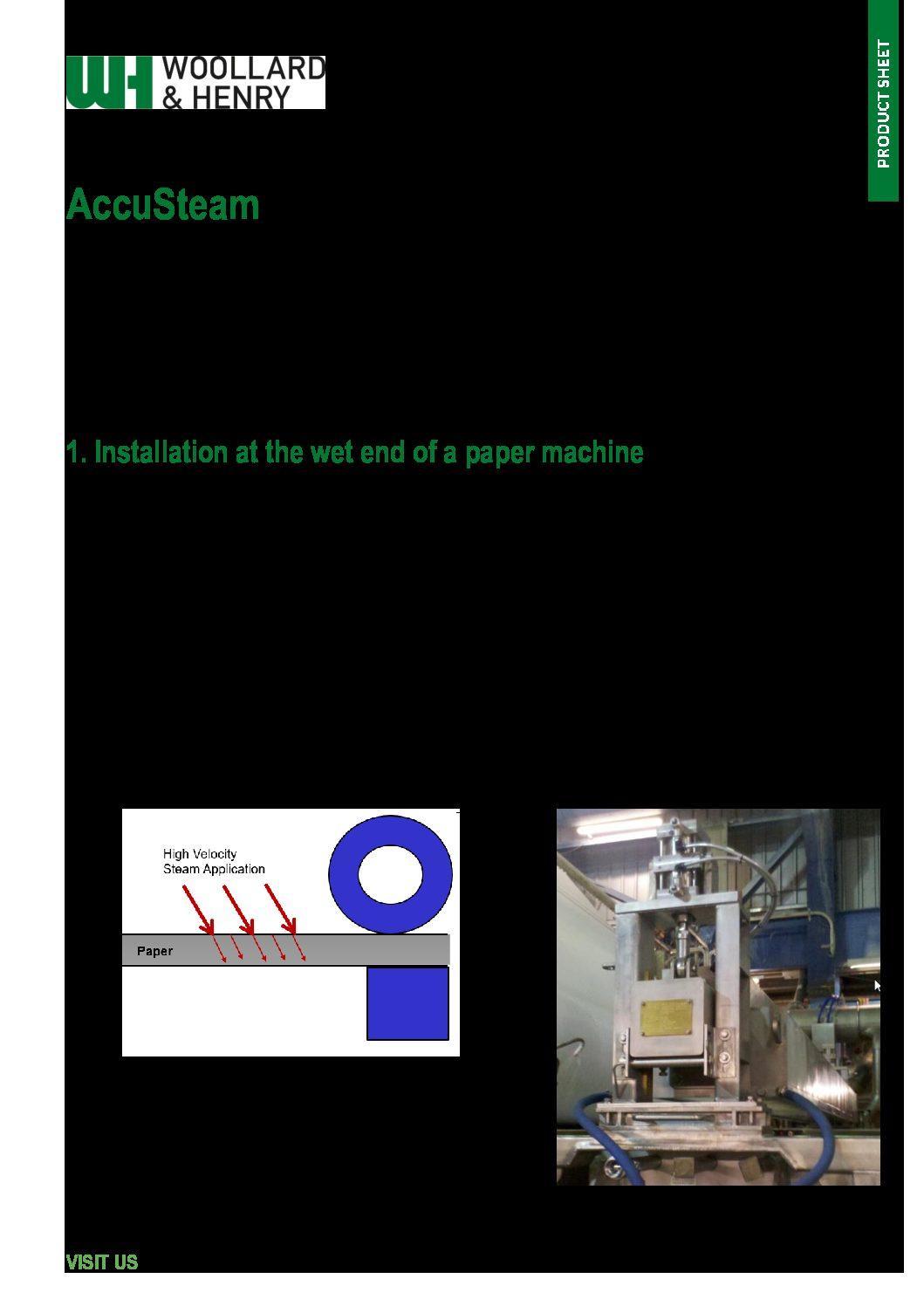

The Woollard & Henry AccuSteam is a tried and tested steambox system improving the papermaking process to control moisture profile and remoisturization of the sheet. AccuSteam Steamboxes are used for installation at the wet end of a paper machine, calender or converting machines. Impressive improvements in production speeds, energy savings and moisture profile control are being noticed on sites where W&H Steam Systems have been implemented.

Steam Systems

AccuSteam Benefits and Results Wet End installation

- Increasing sheet temperature of 10 – 15 °C will improve sheet dryness by approx. 1% for a stock temperature of ≤ 45°C before the AccuSteam unit.

- Installations before the 1st Press nip will result in dryness increase of up to 1.5 – 3% after the Press Section.

- 1% dryness yields a 3 – 5% increase in production or a comparable saving in energy consumption in drying

- Improvement of the dewatering process by zones in CD direction → moisture profile control

- CD moisture 2-sigma improvement up to 50 %

- Reduction of Press Nip loads

AccuSteam Benefit and Results Dry End Application

- Smoothness improvement of up to 15-20 %

- Gloss improvement of up to 10-15 % on newsprint

- Reduction of two sideness

- Increase of printability

- CD Control 2-sigma (Gloss/Smoothness) improvement of up to 50 %

- Reduction of Calender nip loads

- Re-moisturizing of the paper per Position by 2-3 %

- Curl Control

- Surface improvement for coating and converting processes

- Smoothness, Gloss, Moisture and Curl Control by zones in CD direction

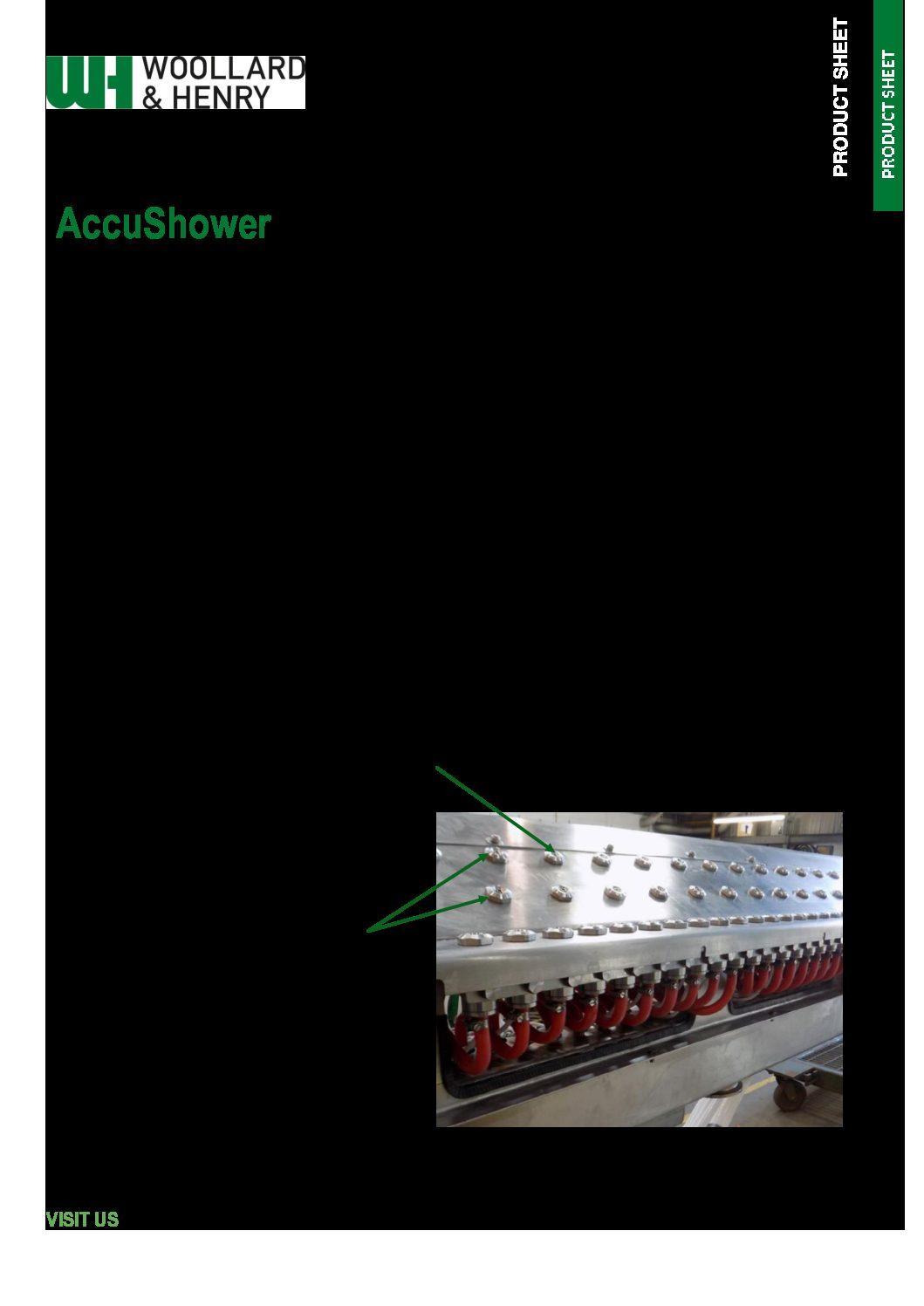

Shower Systems

The Woollard & Henry AccuShower is a tried and tested waterspray system improving the papermaking process to control moisture profile and remoisturization of the sheet. Using the latest fluid technology based on W&H experience and detailed FEM calculations, the AccuShower atomizes the water into extremely small particles forming a fine mist which via offset nozzles ensure perfect water application. The water mist is absorbed by the paper sheet and used to rewet the completed paper in each direction.

AccuShower features and benefits

Moisture control: Increase in moisture and improved moisture control/profile

Remoisturization: Improves controllable range by up to 3%

Profile control: Peak to peak maximum 0.25% moisture difference

Varied positioning: Can be installed within dryer section, cooling cylinder or in front of calendar

Scalable: Showers can be manufactured up to 9500mm

Nozzle spacing: 100mm/double row (off-set) enables 50mm coverage

Interested in knowing more about W&H Steam and Shower system Solutions? We will help you to make good choices that meet your production needs.

Contact Haarla Experts:

- Food

- Water & Air

- Machinery & Equipment

- Industrial

- Health & Wellbeing